The revolutionary robot with smart following technology

by Suman Gupta

- kiloTM has a payload of up to 130 kg and uses 4D radar imaging and the innovative sensors developed by PFF to follow the operator, move autonomously, and travel along more than 100 preset paths

- Based on the follow-me technology deployed on the gita® and gitamini® robots already marketed in the USA, kiloTM offers flexible automation and materials handling solutions for any application or industry

- The Piaggio Group is already planning to implement kiloTM on the new Moto Guzzi production lines to assist operator manoeuvres

Boston (USA), 13 March 2024 – Piaggio Fast Forward (PFF), the Boston-based subsidiary of the Piaggio Group (PIA.MI) active in robotics and mobility for the future, has presented kilo™, a revolutionary robot featuring smart following technology

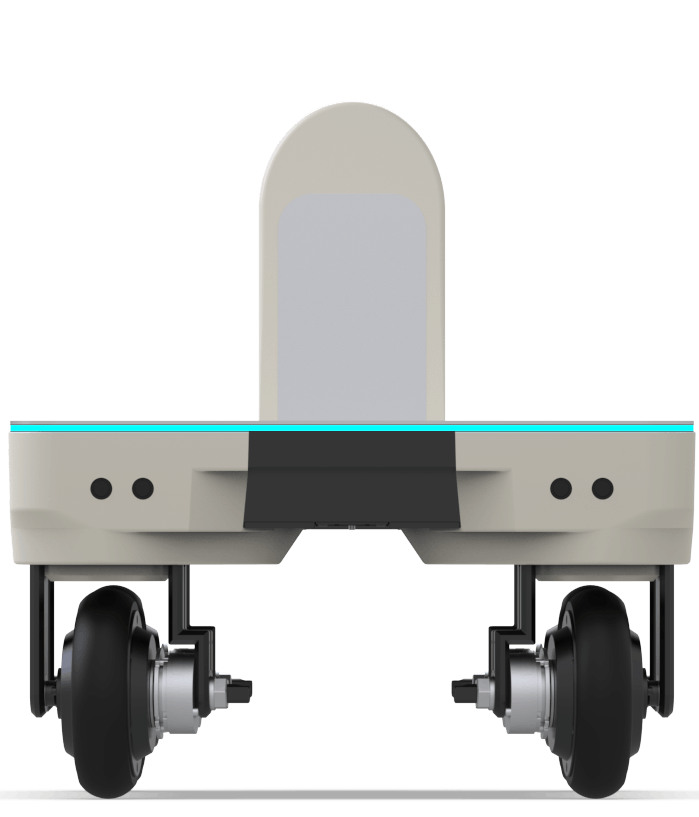

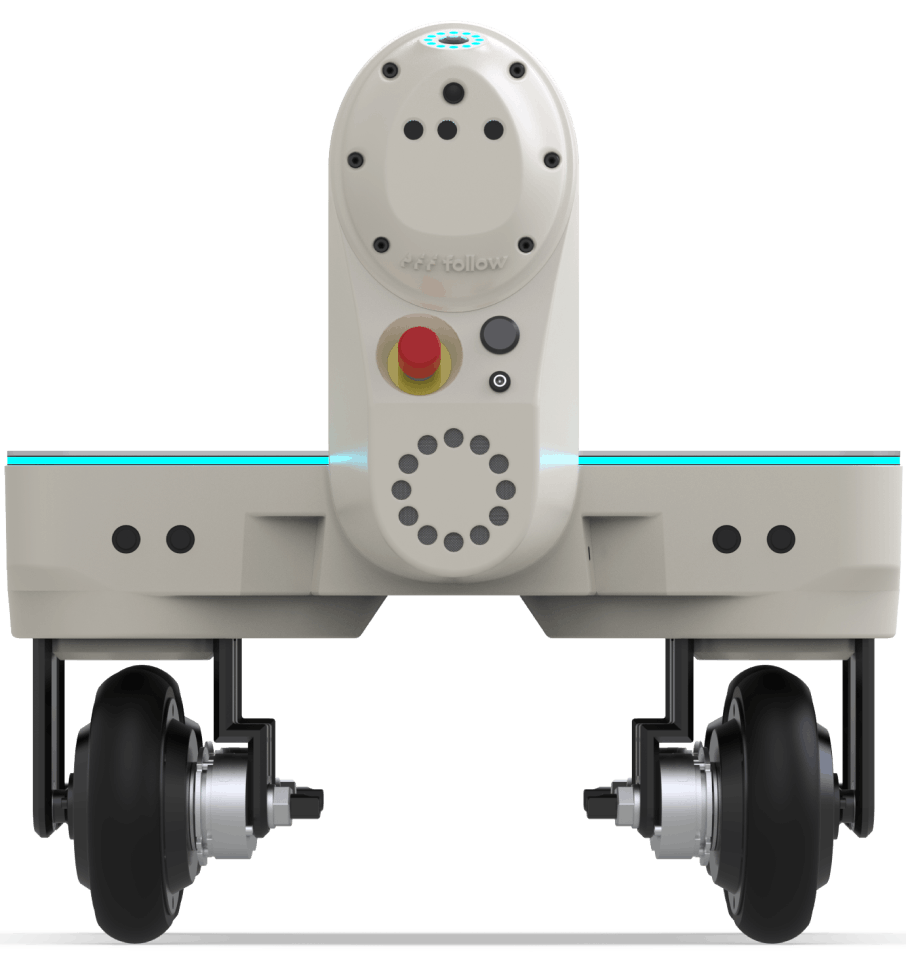

Unveiled at a world preview at Modex, America’s main supply chain tradeshow currently underway in Atlanta (Georgia, USA), kiloTM is a hands-free robotic flat bed with a payload of up to 130 kg. Fitted with the innovative package of sensors and 4D radar imaging developed by PFF, it can follow the operator, move autonomously, and travel along more than 100 paths stored in memory.

“Our robotics technology is augmenting workforces around the world; kiloTM offers customisable options with the ability to utilize state-of-the-art software tools to manage the human-robot relationship,” said Piaggio Fast Forward CEO Greg Lynn. “From manufacturing to any industry that relies on the repetitive movement of goods across campuses and production facilities, PFF’s autonomous technology allows our robots to safely move with and around workers in complex environments, streamlining workflows and increasing productivity.”

kilo™ is designed to work alongside humans, enabling users to move materials naturally and reducing the risk of injury. It marks the first introduction of PFF’s proprietary Travel on Known Paths autonomous behaviour software, and provides operators with an innovative work tool with the ability to follow them or move autonomously.

The kiloTM platform is highly customisable: it can be outfitted with industry- or facility-specific carts or shelving, ensuring the right configuration for any job. In addition, the PFF proTM tools mobile application allows easy management of robot fleets and regular software updating.

The kiloTM platform is highly customisable: it can be outfitted with industry- or facility-specific carts or shelving, ensuring the right configuration for any job. In addition, the PFF proTM tools mobile application allows easy management of robot fleets and regular software updating.

As part of the modernization project at the production facility in Mandello del Lario, the Piaggio Group plans to integrate the kilo™ robot on the new Moto Guzzi production lines to assist operator manoeuvres. kilo™ will subsequently be introduced into the Group’s other production facilities in Italy, India, Vietnam and Indonesia.

kilo™ expands the Piaggio Fast Forward robot range, joining the gita® and gitamini® terrestrial drones, which are already marketed in the USA where the circulation of robots on city streets is regulated. Given appropriate road regulations, the Piaggio Fast Forward robots will be able to travel autonomously on pavements and in pedestrian areas, meeting the growing demand for last-mile and home deliveries.

The PFF Rider Assistance Solution recently made its debut on the new Moto Guzzi Stelvio adventure bike. This is the first time these radar sensors have been designed for use on a motorcycle. Compared with a traditional rider-assistance system based on ultrasound sensors, they offer an extremely broad field of vision and fully reliable monitoring, in any light and environmental conditions. The devices play a fundamental role in active safety, guaranteeing Forward Collision Warning (FCW), Blind Spot Information System (BLIS), Lane Change Assist (LCA) and Following Cruise Control (FCC) functions.